- +36 70 320 5606

- sales@steelstrong.eu

- Debrecen Pallag 044/1 hrsz.

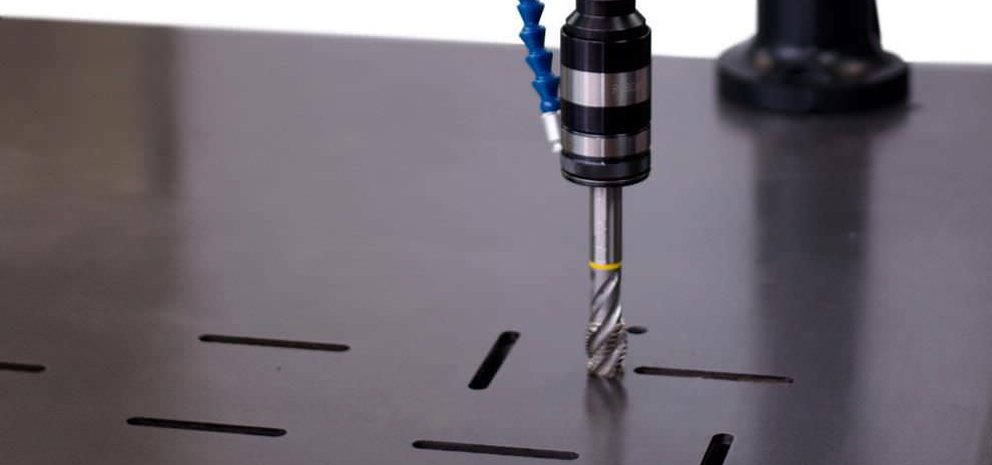

STEELSTRONG offers fast, accurate, and reliable thread tapping services for a wide range of industrial metalworking needs. Using our advanced Roscamat Tiger 002 tapping machine, we ensure high precision and repeatability — whether the task involves medium-volume production or tapping thousands of holes with consistent thread quality.

Our tapping technology is suitable for structural steel, stainless steel (inox), and aluminum components, supporting various thread depths and thread sizes. The process is fully machine-controlled and does not require manual intervention, minimizing errors and ensuring uniform, high-quality results across all parts.

Machinery and equipment manufacturing

Steel structure production

Precision metal part fabrication

Custom metalworking and locksmith projects

Tapping pre-coated components for powder coating

Final machining before assembly

Technological features | Parameters |

|---|---|

Thread size | M3-M24 |

The Roscamat Tiger 002 is a high-performance industrial tapping machine, ideal for precision thread cutting in various metal materials, including those that are traditionally difficult to machine. Thanks to its robust construction, ergonomic design, and steplessly adjustable speed control, this system allows for fast and accurate thread creation—ranging from micro-threads up to M24 metric thread sizes. With accurate positioning and smooth tool guidance, CNC-controlled thread tapping delivers consistent, repeatable, and high-quality results. This makes it a perfect choice for industries that demand fast turnaround, high accuracy, and production efficiency.

STEELSTRONG’s thread tapping service ensures that all threads are burr-free, dimensionally accurate, and fully compliant with international standards. This is particularly critical in applications involving load-bearing assemblies, bolted joints, and the manufacturing of precision-machined components, where exact fit and alignment directly impact performance. Our experienced technicians and automated tapping technology guarantee threads that meet the highest industrial quality standards, providing secure and lasting assembly in every project.

Our thread machining services can be applied across a wide range of base materials. We work with structural steel, stainless steel (INOX), and aluminum, as well as cast components, box sections, steel sheets, and even solid steel profiles. We always select the appropriate tap geometry and tool type to match the material and hole depth, ensuring long-lasting, reliable threading performance across all applications—whether it’s for mechanical engineering, fabrication, or custom manufacturing projects.

One of the key benefits of automated tapping in an industrial environment is the ability to produce consistent and repeatable threads with identical depth, location, and quality. This is especially important for pre-drilled holes from CNC machining, where each thread must match precisely. The Roscamat Tiger 002 enables high-speed, low-risk tapping, making it ideal for large batch production as well. In turn, clients benefit from not only exceptional accuracy but also reduced lead times and lower production costs.

If you are looking for a reliable and precise Tube Bending service that meets all your requirements, choose SteelStrong. Contact us today to get started on your project!