- +36 70 320 5606

- sales@steelstrong.eu

- Debrecen Pallag 044/1 hrsz.

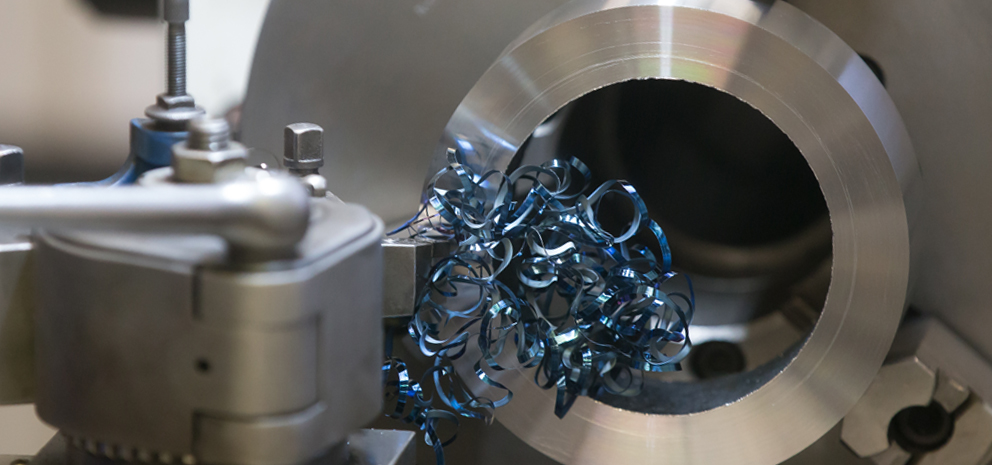

STEELSTRONG’s turning subcontracting service offers a reliable solution for the precision machining of rotational metal components. Our operations utilize the Optimum OptiTurn TH 4615V universal lathe, which is ideally suited for precision turning of steel, stainless steel, aluminum, and various metal alloys.

The machine excels in the machining of internal and external cylindrical surfaces, threads, grooves, stepped geometries, and tapered surfaces. By combining manual and CNC turning methods, we can flexibly meet unique technical requirements and detailed drawing specifications.

Common applications include:

Shafts and rotational parts

Threaded fasteners and connectors

Small series machine parts and prototypes

Wear parts for agricultural machinery

Machine tool components and inserts

Bushings made of bronze, copper, and aluminum

Reproduction of parts for repair purposes

Custom pins, spacers, and fitting elements

Technological features | Pararmeters |

|---|---|

Maximum workpiece size | 460 mm diameter over 1500 mm length |

Accuracy | ±0,05 mm |

The Optimum OptiTurn TH 4615V universal lathe enables the efficient and reliable production of complex geometries and small-batch metal components. Thanks to its manual adjustment capabilities, the machine is perfectly suited for the machining of custom rotational parts, prototypes, and specialized tool components—particularly in cases where CNC programming would be too costly or time-consuming.

With a stable frame, robust drive system, and precise adjustment features, the lathe ensures that machined parts consistently meet standard tolerances—even under manual operation. This is especially valuable when full operator control over the cutting process is required, such as during prototype development, one-off industrial parts manufacturing, or the reproduction of modified components.

Universal turning is not only a fundamental aspect of metalworking but also an essential technology across various industries. We regularly utilize this precision machining method in machine manufacturing, automotive repairs, agricultural machinery maintenance, and spare part reproduction.

Manual turning subcontracting is particularly advantageous in situations requiring rapid response times, custom adaptations, or flexible handling of part dimensions. With no need for CNC programming, conventional lathe work allows immediate project start-up, making it ideal for urgent or variable-parameter orders.

The Optimum OptiTurn TH 4615V is an excellent choice for small-batch and custom part production. Its manual operation eliminates lengthy setup procedures and CNC programming, enabling a swift and cost-effective manufacturing process. This offers a significant advantage for orders where turnaround time, low quantities, or budget efficiency are key priorities.

Whether it’s for repair-driven part reproduction, custom-sized industrial fittings, or prototype manufacturing, universal turning with manual precision can deliver high-quality results on short deadlines—helping clients save both time and costs while achieving excellent technical standards.

Manual turning subcontracting is particularly advantageous in situations requiring rapid response times, custom adaptations, or flexible handling of part dimensions. With no need for CNC programming, conventional lathe work allows immediate project start-up, making it ideal for urgent or variable-parameter orders.

If you are looking for a reliable and precise Tube Bending service that meets all your requirements, choose SteelStrong. Contact us today to get started on your project!