- +36 70 320 5606

- sales@steelstrong.eu

- Debrecen Pallag 044/1 hrsz.

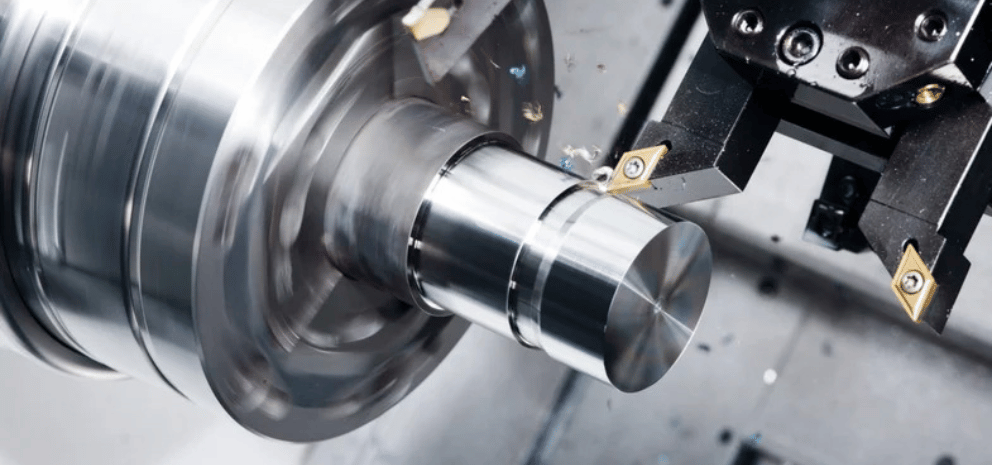

STEELSTRONG offers professional CNC turning services tailored for high-precision machining of carbon steel, stainless steel, aluminum, and various non-ferrous metals. With our state-of-the-art SL-TURN-52 CNC lathe, we are capable of achieving tight tolerances down to ±0.005 mm. This level of accuracy makes our technology ideal for producing industrial components where dimensional stability and fit are critical.

As a trusted subcontracting partner, we handle one-off parts, small batches, and medium-volume series with consistent quality and precision. Whether you need functional machine components, precision connectors, or complex rotational parts, our CNC turning capabilities are perfectly suited for prototyping and production alike.

Common applications include:

Rotational components and shaft couplings for machinery

Threaded automotive parts and bearing housings

Hydraulic and pneumatic system fittings

Stainless steel components for food processing machinery

Agricultural power transmission elements and bushings

Custom metal prototypes and tool inserts

Aluminum and non-ferrous metal connector parts

Low-volume technical part manufacturing

Technological Features | Parameters |

|---|---|

Max. swing diameter over bed | 700 mm |

Max. swing diameter over cross slide | 450 mm |

Distance between centers | 1250 mm |

Current chuck diameter | 8″ |

Max. RPM | 4500 RPM |

Bar capacity | 51 mm |

Driven by | Belt |

Number of ranges | 1(opt.2) |

Number of tool positions | 12 pc |

Tooling | VDI40 |

Number of driven tools (option) | 12 pc |

Maximum speed of tool | 5000 RPM |

Quill / tailstock operation | Mechanical |

Size of internal taper | MT5 |

At STEELSTRONG, we utilize the advanced SL-TURN-52 CNC lathe to deliver high-precision turning services, even for complex geometries. Our digitally controlled system ensures consistent machining within ±0.005 mm tolerances, making it ideal for producing critical components such as fittings, shaft couplings, and locking mechanisms. This level of precision is essential in sectors like mechanical engineering, automotive manufacturing, and hydraulic systems, where dimensional accuracy directly impacts performance and safety.

One of the key advantages of CNC-controlled turning is full repeatability. Every programmed movement and setting can be reproduced exactly, regardless of batch size. This capability is crucial for mass production—where hundreds or thousands of identical parts must meet the same quality standards—but equally important for custom components and prototypes, where every micron counts.

Our CNC turning subcontracting service covers a wide range of materials, including carbon steels, stainless steels (INOX), aluminum, brass, copper, and other non-ferrous metals or industrial alloys. The SL-TURN-52 lathe handles solid bars, tubular profiles, or custom-supplied blanks with ease and accuracy.

During CNC programming, we adapt every machining strategy to the specific characteristics of the material—whether thermal expansion, hardness, or machinability—ensuring that the final parts are not only dimensionally accurate but also durable and well-fitted. This approach is vital in industries where both structural stability and corrosion resistance matter, such as food processing machinery manufacturing or automotive parts production.

At STEELSTRONG, flexibility is just as important as precision. Our capacity allows for fast and accurate production of unique components, small series, and medium-volume part batches. Whether you require a single functional prototype or several hundred identical turned parts, our CNC technology ensures low scrap rates, uniform quality, and efficient cycle times.

This capability is particularly valuable in industries such as mechanical engineering—where customized or machine-specific parts are common—automotive manufacturing, where strict quality control is mandatory, and agriculture, food processing, or metal supply chains, where dimensional consistency and mechanical reliability are critical requirements.

If you are looking for a reliable and precise CNC milling service that meets all your requirements, choose SteelStrong. Contact us today to get started on your project!