- +36 70 320 5606

- sales@steelstrong.eu

- Debrecen Pallag 044/1 hrsz.

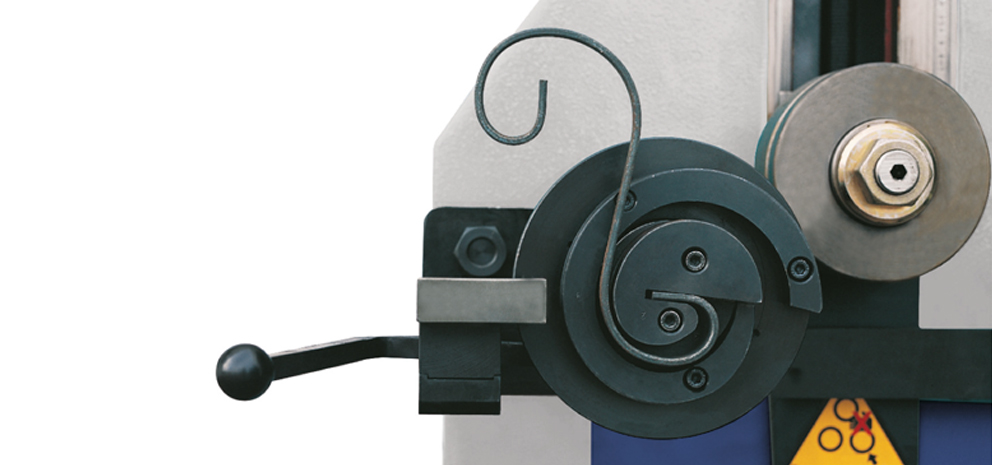

At STEELSTRONG, our profile bending services offer highly accurate forming of various metal profiles, including tubes, rods, and flat bars—precisely shaped to match the specifications provided by our clients. Using our advanced Metallkraft PRM 35 F profile bending machine, we perform contract bending services with speed and reliability, whether the job involves unique curved elements, repeat production runs, or components made from materials of different thicknesses.

Our technology is ideally suited for creating circular and spiral forms from steel, stainless steel (inox), and aluminum, while preserving the cross-sectional integrity of the material—ensuring deformation- and crack-free results.

Common Applications Include:

Structural steel fabrication

Curved staircases, handrails, and safety rails

Metal frames and decorative elements for furniture design

Curved profiles for industrial halls and roofing systems

Architectural and interior metal décor

Industrial machine frames and custom structural supports

Technological features | Parameters |

|---|---|

Max. workpiece size | 30×30 locking section |

Max. workpiece size | 40×40 closed section |

Max. workpiece size | 50×50 closed section |

Max. workpiece size | 26,9 mm diameter tube |

Max. workpiece size | 33,7 mm diameter tube |

Max. workpiece size | 42,4 mm diameter tube |

Max. workpiece size | 60,3 mm diameter tube |

At STEELSTRONG, we use the Metallkraft PRM 35 F profile bending machine to deliver high-precision and repeatable curved profiles across a wide range of structural materials. Whether it’s square tubes, flat bars, T-profiles, angle iron, or round pipes, our CNC-controlled system ensures consistent bending geometry and parameters—even in large production volumes. The machine allows precise adjustments of bend radius, arc length, and direction, guaranteeing identical results for every workpiece. This level of accuracy is critical in the fabrication of steel structures, industrial pipe frames, railings, and architectural metal components, where both dimensional accuracy and visual appearance are paramount.

Our profile bending services are compatible with a wide variety of materials, including structural steel, stainless steel (inox), and aluminum. Throughout the bending process, we carefully adapt our tooling, rollers, and machine settings to the mechanical properties of the given material. This prevents unwanted deformation such as cracking, cross-sectional distortion, or wall wrinkling. The Metallkraft PRM 35 F is ideal for precision bending of both small-diameter rods and larger profiles, making it a versatile solution for manufacturers and fabrication partners in multiple industries.

The STEELSTRONG profile bender is capable of producing a wide array of bend shapes and radii—from simple arcs to spiral curves and complex custom geometries. This flexibility allows us to support a diverse range of applications including curved railings, roof trusses, industrial framing, and decorative metal elements for furniture and architectural use. Even for fully custom projects, we ensure accurate shape replication, aesthetic perfection, and compliance with the highest technical and visual standards—whether for indoor architectural projects or outdoor steel frameworks.

Profile bending is not only suitable for unique or custom shapes—it’s also a cost-effective and scalable solution for large-batch production. Thanks to our precise digital setup and consistent machine control, every piece is produced with identical accuracy and repeatability. This makes our service especially valuable for industrial customers who require uniform results and quick turnaround. With scalable production capacity, we handle small, medium, and large series efficiently and economically, while maintaining competitive pricing and uncompromising quality.

If you are looking for a reliable and precise Tube Bending service that meets all your requirements, choose SteelStrong. Contact us today to get started on your project!